Hydac Type Hydraulic Solenoid Coil 3000489 12V 3000249 24V 300315 110V 3002594 220V

This 3000489 3000249 3000315 3002594 solenoid coil is a hydraulic coil for HYDAC type WSM06020 hydraulic valves. The electromagnetic coil and the armature assembly form an electromagnet. The electromagnet is the energizing solenoid that is learned in middle school. It generates magnetism after being energized. However, it also generates heat after energization. The higher the power of the electromagnet, the greater the heat generated. The heat generated is always more than the heat emitted. It will continue to heat up. When the temperature reaches a certain height, the paint layer on the melt will melt, and then the short circuit will burn out. The electromagnet coil has a thermal effect in addition to the magnetic effect when it is energized. This is inevitable.

Technical parameter of HYDAC type 394287 Hydraulic Coil:

| Model number |

BB18040004 |

| Ref number |

3000489 3000249 300315 3002594 |

| Normal voltage |

DC12V, DC24V, AC110V, AC220V |

| Normal power |

18W, 23W |

| Material |

Plastic, Brass, Iron |

| Wire class |

H |

| Connection |

DIN43650A |

| Application |

HYDAC Type WSM06020 ELectro Valve |

| Hole size |

18 mm |

| Height |

40 mm |

| Width |

36.5 mm |

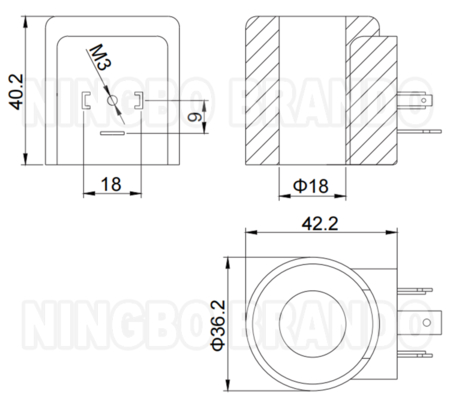

Main dimension of Hydac Type G Hydraulic Solenoid Coil:

Applied in HYDAC Type WSM06020 ELectro Valve 3003138 / 3000249 Solenoid Coil:

Temperature rise of electromagnet in electromagnetic reversing valve operation

The electromagnet is the energizing solenoid that is learned in middle school. It generates magnetism after being energized. However, it also generates heat after energization. The higher the power of the electromagnet, the greater the heat generated. The heat generated is always more than the heat emitted. It will continue to heat up. When the temperature reaches a certain height, the paint layer on the melt will melt, and then the short circuit will burn out. The electromagnet coil has a thermal effect in addition to the magnetic effect when it is energized. This is inevitable.

Electromagnetic reversing valve electromagnets are designed and manufactured in a Class H heat-resistant class to meet the temperature rise during normal operation without worrying about the life of the electromagnet.

Temperature rise of DC electromagnet

The only reason for the temperature rise of the DC electromagnet is the temperature rise of the coil caused by the copper loss. The extent depends on the current density and heat dissipation. In general, the temperature rise of the DC electromagnet is smaller than that of the AC electromagnet.

Temperature rise of AC electromagnet

The temperature rise of the AC electromagnet is caused by the copper loss and the iron loss, depending on the following points:

1. Core eddy current loss and hysteresis loss.

2. Losses caused by circulating power between laminated core rivets.

3. Loss caused by the short circuit.

4. The internal resistance of the excitation causes the coil resistance loss. In addition, it is related to the operating frequency. The higher the frequency, the longer the starting current is, and the higher the temperature rise.

When the electromagnetic reversing valve can not work normally, if the valve plug is unable to move due to external force, the armature cannot be attracted to the normal position after the electromagnet is energized, the magnetic path is blocked, and the coil temperature will rise sharply, especially for AC AC electromagnet. It is very easy to cause the coil to burn out in a short time. Therefore, the cleanliness of the hydraulic system should be paid attention to during use to avoid the malfunction of the electromagnetic reversing valve and prolong the service life.

Welcome to your any question and inquiry!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!