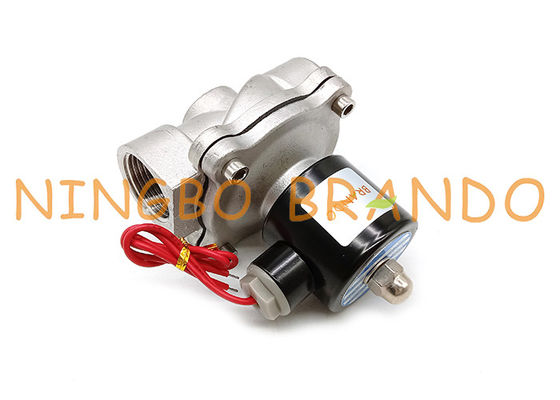

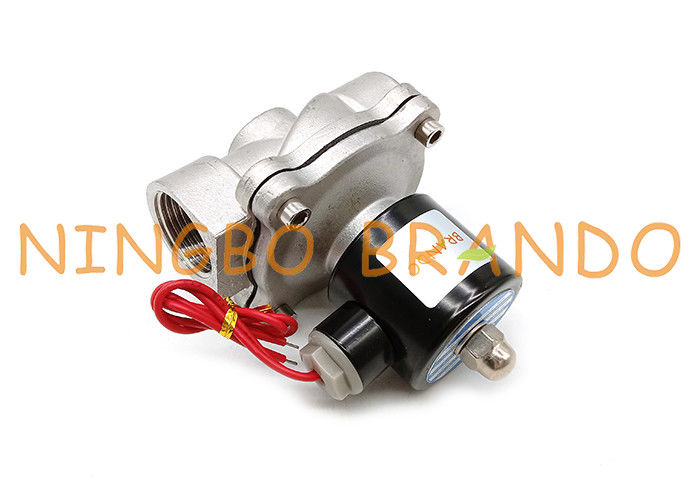

2S250-25 SUW-25 1'' Water Iron Cover Coil Stainless Stianless Solenoid Valve

2S250-25 is a water control valve for sewage treatment used in construction, involving the technical field of mechanical parts.Sewage systems require electromagnetic water valves for flow control.It can be divided into four categories: physical method, chemical method, physical chemical method and biological treatment method according to its principle of action.

Main features of 2S250-25 diaphragm pneumatic water solenoid valve

Corrosion resistance: Most parts are made of stainless steel or cast stainless steel for good corrosion resistance.

Heat resistance: The electromagnetic parts and seals are all made of special high temperature resistant electrical materials and sealing materials, and effective insulation measures are adopted.

Tachnical data of 1'' inch inlet and outlet 2S250-25 pneumatic water solenoid valve:

| Model |

2S025-06 |

2S025-08 |

2S040-10 |

2S160-10 |

2S160-15 |

2S200-20 |

2S250-25 |

2S350-35 |

2S400-40 |

2S500-50 |

| Working medium |

Water, Air, Steam |

| Operating pattern |

Direct drive |

| Acting type |

Normal close |

| Operation fluid viscosity |

20 cst below |

| Pressure |

1.0 Mpa |

| Temperature |

-5-100 ℃ |

Deconstruction diagram of 2S250-25 Solenoid water valves in sewage treatment machines:

Flow direction of 24VDC/220VAC 2S250-25 electromagnetic water diaphragm valves:

Application of 2S250-25 solenoid valves riigation, liquid, flow, gas automatic control valves:

Main ways of sewage treatment with 2S250-25 Corrosion resistant solenoid water valve:

1.Physical law

Through physical action, to separate and recover the insoluble suspended pollutants (including oil film and oil beads) in the sewage, the chemical properties are not changed during the treatment. The physical method is simple and economical to operate. Commonly used are gravity separation, centrifugal separation, filtration, evaporation, crystallization, and the like.

2.Gravity separation (ie precipitation)

Using the principle of different suspended pollutants and water density in the sewage, the suspended solids in the water are separated by gravity sedimentation (or floating). The sedimentation (or floating) treatment equipment has a grit chamber, a sedimentation tank and a grease trap.

In the sewage treatment and utilization method, the precipitation and floating method are often used as pretreatments before other treatment methods. If the biological treatment method is used to treat sewage, it is generally necessary to remove most of the suspended matter in the pre-sinking tank to reduce the treatment load of the biochemical treatment structure, and the biologically treated effluent still has to be treated by the secondary sedimentation tank to ensure the separation of the muddy water. Water quality.

3. Filtration method

The filter medium is used to intercept the suspended matter in the sewage. The filter medium has steel bars, screens, abrasive cloths, plastics, microporous tubes, etc. Commonly used filtration equipments include grids, grids, microfilters, sand filters, vacuum filters, filter presses, etc. (the latter two filters) The machine is mostly used for sludge dewatering).

4. Air flotation (flotation)

The air is introduced into the sewage and precipitated from the water as a carrier in the form of tiny bubbles. The tiny particulate pollutants (such as emulsified oil) whose relative density is close to water adhere to the bubbles and rise to the surface with the bubbles. The pollutants in the sewage can be separated from the sewage. Depending on the way the air is driven in, the air floatation method includes a pressurized dissolved air floatation method, an impeller air floatation method, and a jet air floatation method. In order to improve the air flotation effect, it is sometimes necessary to add a coagulant to the sewage.

Welcome to your inquiry!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!