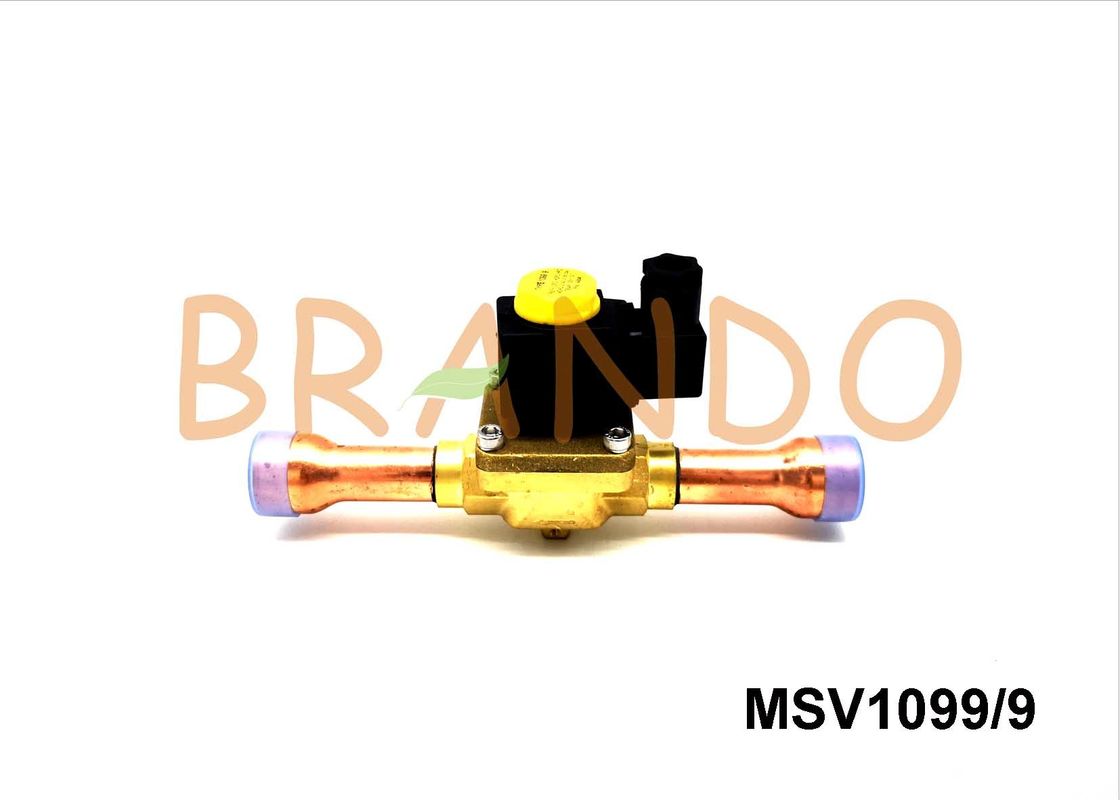

11/8'' ODF Port Size MSV-1099/9 Refrigeration Solenoid Valve In Freezer Machines

Our MSV-1099/9 refrigeration valves are available in a wide range of fluoride refrigerants, and we also offer ammonia refrigeration valves.The MSV refrigeration solenoid valve used in liquid,suction and hot gas lines with fluoridated refrigerants.That is an automatic control parts used in refrigeration system to control the refrigerant to pass or not pass.

Technical information of G1 1/8'' MSV-1099/9 refrigeraiton solenoid valve:

| Model |

MSV1099/9 |

| Connection |

G 1 1/8 Inch |

| Refrigerant |

CFC,HCFC,HFC |

| Media temperature |

-35℃-105℃ |

| Max. opening pressure |

2.5 mpa |

| Min. opening pressure |

0.05 mpa |

| Working pressure |

3 mpa |

| KV value |

5.7 m³/h |

| Length |

106 mm |

| Width |

216 mm |

Overall dimension of MSV-1099/9 G1 1/8 Inch Refirgeration solneoid valve as an automatic control parts:

Internal display of MSV1099/9 Refrigeration electromagnetic valve in cooler:

Diaphragm and pilot of MSV1099/9 solenoid valve in refrigeration compressor units:

Nomal problems of ice maker machines with MSV-1099/9 refrigeration solenoid valves in Air-conditioning:

Symptom 1: No ice or ice is not smooth.

Analysis and repair: If the ice machine can not enter the deicing state, it indicates that the control part has failed. At this time, adjust the ice thickness knob first to see if the ice thickness changes. If it changes, it indicates that the ice thickness detector is normal and the cause of the failure. The electrical control board is damaged, otherwise the ice thickness detector is damaged.

If the ice machine can enter the de-icing state and cannot be detached smoothly or the ice-free time is too long (more than 5 minutes), the reasons are as follows: 1. The foreign matter attached to the surface of the evaporator is not conducive to ice making and ice-removing. Clean the evaporator surface, the water sprinkler and the water storage box; 2. Refrigerant leakage; 3. The heating valve has failed and cannot be opened.

Symptom 2: Some ice cubes are incomplete in shape.

Analysis and overhaul: The cause of the failure is that the nozzle hole is blocked, resulting in poor water flow in the spray pipe. In the state of ice making, use the tweezers to remove the debris in the water outlet hole of the spout, and make the flow in each hole as smooth as possible.

Symptom 3: No ice is produced.

Analysis and repair: The reasons for the failure are: 1. The machine is not placed horizontally, then it can be placed horizontally as required; 2. The ice thickness detector is damaged or the thickness of the adjustment is too small; 3. Solenoid valve is damaged; 4. The refrigerant leaks.

Symptom 4: The pump works, but it does not water.

Analysis and repair: The reasons for the failure are: 1. There is air in the pipeline, and the air in the pump can be discharged; 2. There is too much ice slag at the bottom of the tank. At this time, it is necessary to stop the discharge of ice slag and then restart it. The internal impeller of the pump is seriously worn and the pump needs to be replaced.

Symptom 5: It is not easy to get rid of ice.

Analysis and repair: The reasons for the failure are: 1. The flow rate of the upper water is small or the water supply valve is broken; 2. The heating valve is bad or the heating is insufficient; 3. The surface of the evaporator is too dirty, that is, the scale is too much; The thickness of the ice block setting is too thick.

Symptom 6: Water replenishment cannot be performed automatically.

Analysis and overhaul: First check the water inlet condition of the pipeline. If it is not water, turn on the water source and restart it. If the inlet pipe is normal, it indicates that the inlet solenoid valve is faulty and needs to be replaced.

Welcome to your inquiry!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!